In-Mould Labelling...

Performance,

Durability

Performance,

Durability

About In-Mould Labels

The Method

In-mould labelling (IML) is the method of decorating a moulded container by placing a pre-made label inside the moulding tool cavity prior to forming the plastic container. The result is a moulded and decorated one piece item.

The Label

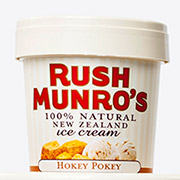

Typically offset printed on very light weight polypropylene film and die-cut to shape then supplied to the moulder. The most common application is thin-wall injection moulded containers for food products, also made from polypropylene.

The Benefit

The benefit of the concept is its ability to have higher quality printing covering multiple surfaces of the container to enhance its consumer appeal. The iml labels are permanently bonded to the container and are impervious to the affects of moisture, condensation and freezing.

Environmentally Friendly

Environmentally iml labelled containers are beneficial because they are washable, re-usable, recyclable and very light weight. They avoid the use of secondary labelling operations requiring additional equipment, energy, adhesives and backing material.